Central Line Dressing Change: A Comprehensive Guide

Central line dressing changes require meticulous technique to prevent complications.

Resources like Weber State University’s YouTube guide and protocols offer detailed PDF instructions.

Proper training and adherence to guidelines are crucial for patient safety.

Central lines are vital for delivering medications and fluids‚ but they carry a risk of infection. Maintaining a sterile environment during dressing changes is paramount. Understanding the principles of central line care‚ often detailed in PDF protocols‚ is essential for all healthcare professionals. These protocols‚ like those referenced from Weber State University resources‚ emphasize meticulous technique to minimize complications.

Proper central line care isn’t just about applying a dressing; it’s a comprehensive approach encompassing assessment‚ preparation‚ execution‚ and documentation. A central line dressing change PDF will typically outline each step‚ from gathering supplies to educating the patient. Consistent adherence to these guidelines significantly reduces the incidence of central line-associated bloodstream infections (CLABSIs).

Effective care requires a dedicated team committed to best practices and continuous learning. Resources available online‚ including instructional videos‚ supplement written PDF guides‚ providing a multi-faceted learning experience.

Importance of Sterile Technique

Sterile technique is non-negotiable when performing a central line dressing change. The primary goal is to prevent the introduction of microorganisms into the bloodstream‚ thereby avoiding central line-associated bloodstream infections (CLABSIs). Detailed PDF guidelines‚ often sourced from institutions like Weber State University‚ meticulously outline the steps required to maintain sterility throughout the procedure.

Compromising sterile technique – even momentarily – can have severe consequences for the patient. This includes careful hand hygiene‚ the use of sterile gloves‚ drapes‚ and solutions. A comprehensive central line dressing change PDF will emphasize the importance of a sterile field and the avoidance of contamination.

Adhering to these protocols isn’t merely a procedural requirement; it’s a critical component of patient safety. Consistent application of sterile technique demonstrably reduces infection rates and improves patient outcomes. Resources available online reinforce the significance of this practice.

Gathering Supplies for the Dressing Change

Prior to initiating a central line dressing change‚ meticulous preparation and gathering of all necessary supplies are essential. A detailed PDF checklist‚ often found in institutional protocols‚ ensures nothing is overlooked. Core supplies include sterile gloves‚ a sterile drape‚ skin antiseptic (Chlorhexidine or Povidone-Iodine)‚ a Biopatch (if prescribed)‚ transparent dressing or gauze and tape‚ and sterile saline.

Additional items may include a sterile measuring device for catheter site assessment‚ a gown if splashing is anticipated‚ and appropriate personal protective equipment (PPE). The central line dressing change PDF should specify quantities and sizes of each item.

Having all supplies readily available minimizes interruptions during the procedure‚ reducing the risk of contamination and promoting efficiency. Confirming the expiration dates of all sterile items is also a crucial pre-procedure step‚ ensuring optimal patient safety.

Patient Assessment Before Procedure

A thorough patient assessment is paramount before any central line dressing change. Review the patient’s medical history‚ focusing on allergies‚ particularly to iodine or chlorhexidine‚ as detailed in a comprehensive PDF protocol. Assess the patient’s current condition‚ noting any signs of infection‚ such as fever‚ redness‚ swelling‚ or drainage at the catheter exit site.

Verify the physician’s orders and ensure the dressing change is indicated. Evaluate the patient’s level of consciousness and ability to cooperate during the procedure. A central line dressing change PDF guide will emphasize the importance of explaining the procedure to the patient‚ addressing any concerns‚ and obtaining informed consent.

Document any pre-existing conditions or observations before commencing the dressing change‚ providing a baseline for post-procedure comparison and evaluation.

Hand Hygiene Protocol

Strict adherence to a rigorous hand hygiene protocol is non-negotiable during a central line dressing change‚ as highlighted in any reputable PDF guideline. Begin with performing hand hygiene using either soap and water or an alcohol-based hand rub. If hands are visibly soiled‚ soap and water are preferred‚ ensuring a thorough 20-second scrub.

Following the initial hand hygiene‚ don non-sterile gloves. A central line dressing change PDF will clearly state that hand hygiene must be performed before putting on gloves. After glove application‚ perform hand hygiene again‚ ensuring all surfaces of the gloves are covered with the antiseptic solution.

Throughout the procedure‚ if gloves become contaminated‚ they must be changed immediately‚ followed by re-performing hand hygiene. This meticulous approach minimizes the risk of introducing pathogens into the central line system.

Removing the Old Dressing

Carefully removing the old dressing is the first step‚ detailed in any central line dressing change PDF. Begin by gently loosening the edges of the dressing‚ utilizing a slow and deliberate technique to minimize trauma to the skin. Avoid abrupt or forceful removal‚ which can cause discomfort and potentially disrupt the catheter site.

A PDF guide will emphasize the importance of observing the catheter exit site during dressing removal. Note any signs of redness‚ swelling‚ drainage‚ or pain. If any of these are present‚ document them immediately.

Once the dressing is removed‚ carefully inspect the securement device. Assess its integrity and ensure it hasn’t caused any skin irritation or damage. Dispose of the old dressing appropriately as contaminated waste‚ following hospital protocol.

Gentle Removal of Securement Device

Gentle removal of the securement device is paramount‚ as detailed in a central line dressing change PDF. These devices‚ like StatLocks or Tegaderms‚ hold the catheter in place. Avoid pulling directly on the catheter itself; instead‚ focus on carefully lifting the edges of the securement device.

A PDF resource will likely advise using a skin protectant or adhesive remover under the device to facilitate its removal and minimize skin stripping. Slow‚ steady pressure is key‚ working around the perimeter of the device.

Inspect the skin underneath for any signs of irritation‚ maceration‚ or damage. Document any observations. If the device is difficult to remove‚ do not force it; consult with a more experienced clinician. Proper technique prevents unnecessary patient discomfort and maintains skin integrity.

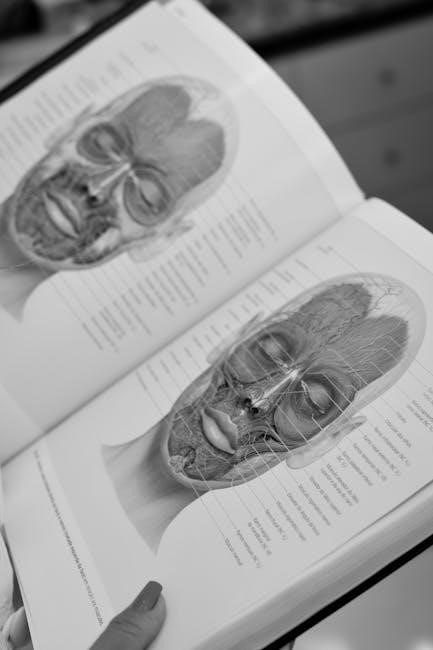

Assessing the Catheter Exit Site

Assessing the catheter exit site is a critical step‚ thoroughly outlined in a central line dressing change PDF. This involves a visual and tactile examination for signs of infection or complications. Look for redness‚ swelling‚ tenderness‚ or drainage at the insertion point.

A PDF guide will emphasize palpating the site to check for induration (hardening) or tunneling. Note the color and amount of any drainage‚ and document its characteristics (purulent‚ serous‚ sanguineous).

Assess the surrounding skin for signs of cellulitis or skin breakdown. Carefully observe the catheter itself for cracks‚ kinks‚ or dislodgement. Any concerning findings warrant immediate reporting to the healthcare provider and potential intervention‚ as detailed in the protocol.

Observing for Signs of Infection

A central line dressing change PDF will detail meticulous observation for infection indicators. Beyond the exit site‚ systemic signs are crucial. Monitor the patient for fever (temperature above 100.4°F or 38°C)‚ chills‚ and unexplained fatigue.

Assess for signs of sepsis‚ including altered mental status‚ hypotension‚ and rapid heart rate. Local signs include increased redness‚ swelling‚ pain‚ and purulent drainage from the exit site. A PDF resource will highlight the importance of noting any odor associated with the drainage.

Document any tenderness along the catheter tract. Remember‚ early detection is key. Prompt reporting of suspected infection allows for timely intervention‚ preventing potentially life-threatening complications‚ as emphasized in comprehensive central line care guidelines.

Cleaning the Catheter Exit Site

A detailed central line dressing change PDF emphasizes thorough cleaning of the exit site; Begin with sterile technique‚ utilizing appropriate personal protective equipment. Select an antiseptic solution – Chlorhexidine in 70% isopropyl alcohol is often preferred‚ though Povidone-Iodine is also used‚ depending on institutional protocols.

The PDF will illustrate a circular scrubbing motion‚ starting at the insertion site and moving outwards‚ covering a wide area. Avoid excessive pressure that could cause trauma. Ensure complete removal of any debris or old dressing adhesive.

Crucially‚ allow the antiseptic to dry completely before applying a biopatch or new dressing. This drying period is vital for optimal antiseptic efficacy. A wet exit site compromises the dressing’s protective barrier and increases infection risk‚ as detailed in best practice guidelines.

Antiseptic Solution Selection (Chlorhexidine‚ Povidone-Iodine)

A comprehensive central line dressing change PDF outlines the considerations for antiseptic choice. Chlorhexidine Gluconate (CHG) in 70% isopropyl alcohol is frequently recommended due to its persistent antimicrobial activity‚ offering prolonged protection against skin flora. However‚ Povidone-Iodine (Betadine) remains a viable option‚ particularly for patients with Chlorhexidine allergies.

The PDF will detail that the selection often depends on institutional policy and patient-specific factors. CHG is generally preferred for long-term catheter sites‚ while Povidone-Iodine may be used for single-use or short-term applications.

Regardless of the choice‚ proper application technique is paramount. Always verify patient allergies before use and adhere to manufacturer’s instructions for dwell time and concentration. Consistent use of the selected agent is key to minimizing infection risk.

Proper Application Technique of Antiseptic

A detailed central line dressing change PDF emphasizes a standardized antiseptic application technique. Begin with a circular motion‚ starting at the catheter exit site and moving outwards in progressively larger circles. This “bullseye” method ensures complete coverage of the surrounding skin.

The PDF will instruct to apply sufficient solution to visibly wet the skin‚ maintaining a generous field. Allow the antiseptic to air dry completely – do not wipe it off‚ as this diminishes its effectiveness. Drying time is crucial for optimal antimicrobial action‚ typically 30-60 seconds for Chlorhexidine and similar for Povidone-Iodine.

Avoid excessive saturation that could cause pooling under the dressing. Consistent technique‚ following the guidelines in the PDF‚ minimizes the risk of catheter-related bloodstream infections and promotes optimal patient outcomes.

Drying the Exit Site Thoroughly

A comprehensive central line dressing change PDF consistently stresses the critical importance of complete drying of the catheter exit site. This step is non-negotiable‚ as moisture compromises the antiseptic’s efficacy and increases infection risk. Utilize sterile gauze pads to gently pat – never rub – the area dry.

The PDF will likely detail avoiding any residual pooling of antiseptic solution beneath the new dressing. Ensure the skin is visibly dry to the touch before proceeding with subsequent steps‚ such as Biopatch application or dressing application.

Complete drying creates an optimal environment for adhesion of the dressing and minimizes bacterial growth. Following the PDF’s instructions meticulously ensures a secure and protective barrier‚ safeguarding the central line and promoting patient well-being.

Applying a Biopatch (If Applicable)

Many central line dressing change PDF guides detail the application of a Biopatch‚ a semi-permeable dressing designed to provide an additional barrier against microbial invasion at the catheter exit site. If indicated‚ carefully remove the Biopatch from its packaging‚ maintaining sterility.

The PDF will illustrate correct placement‚ typically centering the Biopatch directly over the exit site‚ ensuring complete coverage. Avoid any wrinkles or folds that could harbor bacteria. Gently adhere the Biopatch to the skin‚ applying even pressure.

Secure the Biopatch’s edges firmly‚ but without constricting the catheter. Proper adherence is vital for maintaining a protective seal. Refer to the PDF for specific instructions regarding Biopatch size and application techniques based on catheter type and patient needs.

Correct Placement of Biopatch

Central line dressing change PDF protocols emphasize precise Biopatch placement. The Biopatch should be centered directly over the catheter exit site‚ creating a secure seal. Ensure the adhesive surface completely surrounds the site‚ extending approximately 2-3 centimeters beyond the exit point in all directions‚ as detailed in the PDF.

Avoid covering the catheter itself with the Biopatch; it’s intended for skin application only. The PDF will often show diagrams illustrating the correct positioning‚ highlighting the importance of avoiding wrinkles or folds in the dressing. These imperfections can compromise the barrier and increase infection risk.

Confirm the Biopatch is firmly adhered to clean‚ dry skin. Proper alignment and complete coverage‚ as shown in the PDF‚ are crucial for maximizing its protective benefits and minimizing potential complications.

Securing the Biopatch

Central line dressing change PDF guidelines stress the importance of firmly securing the Biopatch to ensure a stable‚ protective barrier. After correct placement‚ gently but firmly press the Biopatch onto the skin for at least 30 seconds‚ activating the adhesive. Avoid excessive pressure that could damage the catheter or surrounding tissue‚ as detailed in the PDF.

The PDF may recommend using additional transparent dressings or tape to reinforce the Biopatch’s edges‚ particularly in areas prone to friction or movement. Ensure any additional securing materials do not obstruct the catheter exit site or impede visualization for infection assessment.

Regularly assess the security of the Biopatch during routine monitoring. A loose or lifting Biopatch compromises the sterile barrier and necessitates immediate replacement‚ following the steps outlined in the PDF protocol.

Applying the New Dressing

Central line dressing change PDF protocols detail the application of a new dressing post-cleaning. The choice between a transparent dressing and gauze with tape depends on institutional policy and patient factors‚ as outlined in the PDF. Transparent dressings allow for continuous visualization of the site‚ aiding in early detection of complications.

When using a transparent dressing‚ ensure it’s larger than the Biopatch (if applicable) and extends several inches beyond the catheter exit site. Avoid wrinkles or air bubbles‚ as these can create potential entry points for microorganisms‚ per the PDF instructions.

If gauze and tape are used‚ apply sterile gauze pads to cover the exit site‚ followed by secure tape application. The PDF emphasizes avoiding excessive tightness that could constrict blood flow or cause skin irritation. Regularly assess the dressing for securement and signs of contamination.

Transparent Dressing vs. Gauze and Tape

Central line dressing change PDF guidelines often present a choice between transparent dressings and traditional gauze and tape. Transparent dressings‚ favored for their visibility‚ allow continuous monitoring of the catheter exit site for signs of infection – redness‚ swelling‚ or drainage – as detailed in the PDF resources.

Gauze and tape‚ while cost-effective‚ require more frequent changes and obscure the exit site‚ potentially delaying the detection of complications. The PDF protocols highlight that gauze must be sterile and applied with meticulous technique to maintain a barrier against microorganisms.

The selection depends on patient-specific factors‚ institutional protocols‚ and clinician preference. Some PDFs recommend transparent dressings for patients with minimal drainage‚ while gauze may be preferred for those with heavier exudate. Proper application and securement are paramount for both methods.

Layering of Dressing Components

Central line dressing change PDF guides emphasize a layered approach for optimal protection. Typically‚ this begins with a split-dosing application of antiseptic solution‚ followed by a potential Biopatch‚ as outlined in many PDF protocols. The Biopatch‚ if used‚ provides an additional antimicrobial barrier at the catheter exit site.

Next‚ a transparent dressing is applied‚ ensuring complete coverage of the exit site and securement device. Some PDFs suggest a foam dressing under the transparent film for patients with fragile skin or significant drainage‚ offering cushioning and absorption.

The layering aims to create a multi-faceted barrier against contamination while allowing for visualization of the site. PDF resources consistently stress avoiding excessive layers‚ which can impede airflow and potentially promote moisture buildup. Proper sequencing and securement are vital for maintaining the integrity of each layer.

Securement of the Dressing

Central line dressing change PDF guidelines consistently highlight the importance of secure dressing fixation. The goal is to prevent dislodgement and maintain a sterile barrier. Transparent dressings often have an adhesive border‚ ensuring a firm seal against the skin‚ as detailed in many PDF protocols.

If additional securement is needed – particularly with larger catheters or patients with active movement – medical tape is applied. PDF resources recommend using hypoallergenic tape to minimize skin irritation. Tape strips should be applied firmly‚ overlapping the dressing edges without covering the catheter itself.

Proper securement prevents catheter-related bloodstream infections (CRBSIs). PDFs emphasize checking the securement after application to confirm stability. Regular assessment during patient care is also crucial to ensure the dressing remains intact and functional‚ as outlined in comprehensive PDF training materials.

Post-Procedure Assessment and Documentation

Central line dressing change PDF protocols universally stress thorough post-procedure evaluation. Immediately after application‚ assess the exit site for any bleeding; apply gentle pressure if needed. Observe for signs of discomfort or patient report of pain‚ documenting any findings. A PDF checklist can aid in systematic assessment.

Crucially‚ document the procedure in the patient’s medical record. This includes the date‚ time‚ type of dressing applied (referencing the PDF guidelines followed)‚ and the condition of the exit site – noting any redness‚ swelling‚ or drainage.

PDF resources emphasize documenting any complications encountered and interventions performed. Accurate and detailed documentation is vital for continuity of care and tracking potential catheter-related issues. Consistent documentation‚ guided by a PDF template‚ supports quality improvement initiatives and ensures accountability.

Checking for Bleeding or Discomfort

Following the new dressing application‚ as detailed in a standard central line dressing change PDF‚ immediate assessment for bleeding is paramount. Gently palpate around the catheter exit site‚ observing for any visible hematoma formation or oozing. Apply direct‚ yet gentle‚ pressure with a sterile gauze if minor bleeding occurs‚ documenting the episode.

Simultaneously‚ assess the patient for any discomfort or pain at the insertion site. Utilize a pain scale and document the patient’s subjective experience. A PDF checklist can prompt this systematic evaluation.

The PDF protocol should also guide you to inquire about any unusual sensations‚ such as warmth‚ tingling‚ or burning. These could indicate potential complications. Document all findings accurately‚ as they are crucial for ongoing monitoring and early intervention‚ as outlined in the central line dressing change PDF.

Documenting the Date‚ Time‚ and Procedure

Thorough documentation is a critical component of central line dressing change care‚ as emphasized in any comprehensive central line dressing change PDF. Record the date and precise time of the procedure in the patient’s medical record. This establishes a clear timeline for tracking care and identifying any potential issues.

Detail the specific steps taken during the dressing change‚ referencing the facility’s PDF protocol. Include the type of dressing applied (transparent‚ gauze and tape‚ biopatch if used)‚ the antiseptic solution utilized‚ and any observations made regarding the catheter exit site.

A standardized PDF form can streamline this process. Document any complications encountered‚ such as bleeding‚ resistance during dressing removal‚ or signs of infection. Accurate and complete documentation ensures continuity of care and facilitates effective communication among healthcare providers‚ as highlighted in the central line dressing change PDF.

Patient Education on Central Line Care

Empowering patients with knowledge about their central line is paramount. A readily available central line dressing change PDF can serve as a valuable educational tool. Explain the importance of keeping the line clean and dry‚ and demonstrate proper hand hygiene techniques before touching the line or dressing.

Instruct patients to immediately report any signs of infection – redness‚ swelling‚ pain‚ drainage – to their healthcare provider. Emphasize the ‘do not touch’ rule; they should avoid manipulating the line or dressing themselves.

Review the schedule for routine dressing changes and explain what to expect during the procedure. Provide a copy of the central line dressing change PDF for home reference; Reinforce that any concerns should be addressed promptly‚ fostering a collaborative approach to central line care and minimizing potential complications.